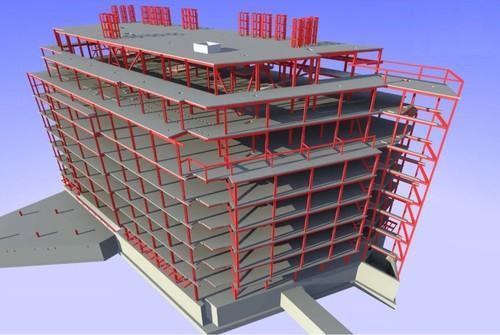

MEP BIM Modeling

MEP BIM Modeling Services follow an integrated approach to mechanical, electrical, and plumbing systems, widely used in industrial, commercial, and residential projects. These services ensure that every building structure is equipped with efficient MEP systems, which are essential for operational performance and structural reliability.

MEP BIM Modeling

MEP BIM Modeling Services are essential for delivering precise and coordinated construction drawings. We provide these services to general contractors, engineers, consultants, MEP dealers, and processors, helping them create accurate drawings across all MEP trades. MEP forms the backbone of construction projects, and our detailed coordination drawings enable effective collaboration between engineering disciplines. At Acura BIM, one of India’s leading MEP modeling and design companies, our professionals use advanced tools like AutoCAD MEP and Revit MEP to deliver top-tier solutions. We’re committed to offering the best outcomes using the latest technologies.

MEP BIM Modeling Services

Mechanical System Modeling

Create detailed 3D models of HVAC equipment, ductwork, air-handling units, chillers and distribution networks to ensure precise design and installation.

Electrical System Modeling

Model electrical layouts including lighting, power distribution, cable trays, conduits and switchgear to support integrated coordination and installation planning.

Plumbing & Piping Modeling

Develop intelligent 3D models for plumbing, drainage, gas piping, fire-fighting systems and related components for accurate documentation and installation.

MEP Coordination & Clash Detection

Integrate mechanical, electrical and plumbing models with architectural and structural trades to detect and resolve clashes early in the BIM process.

Scan-to-BIM for MEP Systems

Convert point-cloud or laser scan data of existing facilities into as-built 3D MEP models, enabling renovation, retrofit or facility-management workflows.

LOD & Asset Data Integration

Produce MEP models up to high Levels of Development (LOD) and embed metadata (asset IDs, manufacturer info, maintenance details) to support lifecycle management.

Measuring Our Success Through Your Growth

Industries We Serve

We have a BIM solution for everything your project demands.

HEALTHCARE

RESIDENTIAL

HOSPITALITY

RETAIL & COMMERCIAL

INFRASTRUCTURE

TRANSPORTATION

EDUCATION

ENERGY & INDUSTRIAL

DATA CENTRE

MIXED-USE

Why Choose Us

Precision Engineering

At ACURABIM we deliver highly accurate 3D modelling and drafting services tailored for the AEC industry whether architectural, structural or MEP systems.

Seamless Collaboration

We facilitate smooth coordination between architects, engineers and contractors through our BIM workflow that supports clash detection, real-time updates and shared data access

End-to-End Delivery

From 2D planning and 3D modelling to 4D sequencing and 5D cost integration, ACURABIM supports your project through all phases. Whether it's conceptual design or construction.

Cost & Time Efficiency

By using smart BIM processes, detailed drafting and thorough documentation, we help you reduce construction delays, avoid costly mistakes and optimise material usage.

General Questions

What is MEP BIM Modeling?

MEP BIM (Building Information Modeling) Modeling refers to the process of creating and managing digital representations of the mechanical, electrical, and plumbing systems in a building using BIM technology. This 3D model integrates various MEP systems (HVAC, electrical, plumbing, fire protection, etc.) with the building’s architectural and structural elements. The goal is to improve collaboration, enhance efficiency, detect design conflicts, and optimize the performance of the building’s systems throughout its lifecycle.

What are the main components of MEP BIM Modeling?

MEP BIM modeling typically includes the following components:

- Mechanical Systems (HVAC): Includes ducts, air handling units, vents, chillers, boilers, and other HVAC components designed for heating, ventilation, and air conditioning.

- Electrical Systems: Includes lighting, power distribution, wiring, panels, circuits, transformers, and outlets.

- Plumbing Systems: Includes pipes, fixtures, drainage, water supply systems, and other plumbing components.

- Fire Protection Systems: Includes sprinklers, fire alarms, and emergency exit lighting integrated into the building’s MEP system.

- Coordination with Architecture and Structure: The MEP model is integrated with the architectural and structural elements to avoid clashes and ensure a seamless fit within the building design.

What are the benefits of MEP BIM Modeling?

MEP BIM Modeling offers several key advantages:

- Improved Collaboration: By integrating mechanical, electrical, and plumbing systems into a single 3D model, MEP BIM fosters better coordination between architects, engineers, contractors, and subcontractors.

- Clash Detection and Resolution: MEP BIM allows for early detection of clashes or conflicts between systems and structural elements, avoiding costly rework and delays during construction.

- Energy Efficiency and Performance Optimization: MEP models help simulate building systems’ performance, enabling the design of energy-efficient systems and improving overall building sustainability.

- Reduced Costs and Time: With accurate, coordinated models, MEP BIM minimizes the need for redesigns and rework, reducing construction time and material waste.

- Better Maintenance and Operation: The model provides a comprehensive digital record of all MEP systems, which can be useful for future maintenance, system upgrades, and building management.

- Improved Accuracy and Documentation: BIM provides highly accurate and detailed documentation, ensuring that construction is done to precise specifications.

How does MEP BIM Modeling work?

The MEP BIM Modeling process typically follows these steps:

- Initial Design Input: Architects and engineers input data into the BIM model, including building geometry, spatial requirements, and system specifications.

- System Modeling: MEP engineers model the mechanical, electrical, and plumbing systems in 3D, defining their layout, components, and interactions.

- Clash Detection: The system undergoes clash detection, where potential conflicts between systems or with structural elements are identified and addressed before construction begins.

- Coordination: The MEP model is integrated with the architectural and structural models to ensure coordination across disciplines and to prevent interference with building systems.

- Detailed Documentation: Once the model is finalized, detailed drawings, schedules, and specifications are generated for construction and system installation.

- Construction and Installation: The model serves as a guide during the construction process, ensuring that systems are installed accurately and according to specifications.

- Post-Construction: After construction, the BIM model can be handed over to facility managers for use in ongoing maintenance and system operations.

What software is used for MEP BIM Modeling?

Several software tools are commonly used for MEP BIM modeling, including:

- Revit: The leading BIM software for MEP modeling, Revit allows for the creation of detailed 3D models for mechanical, electrical, and plumbing systems, as well as integration with architectural and structural elements.

- AutoCAD MEP: A version of AutoCAD designed for MEP systems, providing specialized tools for creating, drafting, and modeling MEP systems.

- Navisworks: Used for clash detection, coordination, and simulation of the complete MEP systems along with architectural and structural models.

- Trane Trace 700: Used for HVAC load calculations and energy modeling, optimizing heating and cooling systems for efficiency.

- Bentley Systems (AECOsim): A BIM software used for designing and managing MEP systems, offering tools for coordination and integration with other systems.

- Plancal nova: Primarily used for MEP system planning and design, particularly in European markets, for a wide range of building types.

- MagiCAD: A software used specifically for MEP design, offering 3D modeling and integrated BIM features.

What are the costs of MEP BIM Modeling Services?

The cost of MEP BIM Modeling services depends on:

- Project Size and Complexity: Larger, more complex projects with multiple MEP systems will incur higher costs due to the amount of work and coordination involved.

- Software and Tools Used: The use of advanced software and tools may increase the overall cost.

- Level of Detail: Highly detailed models or those requiring significant customization will be more expensive.

- Geographical Location: Costs may vary depending on the region or country, with different labor rates and software licensing costs.

On average, MEP BIM Modeling services can range from $50 to $150 per hour, depending on these factors. For larger projects, the cost can range from $10,000 to $50,000 or more.

Enquire Now

Our Work