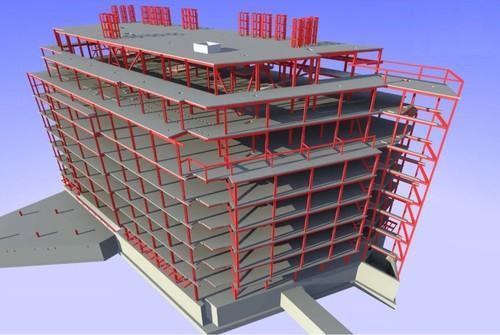

Shop drawing for structural steel detailing

Shop drawings for structural steel detailing are detailed drawings that provide information about the fabrication and installation of structural steel components in a construction project. These drawings are typically created by professional structural steel detailers using computer-aided design (CAD) software. Here are some key components typically included in shop drawings for structural steel detailing.

- Home

- Services

- Structural Modeling Services

- Shop drawing for structural steel detailing

Services for Shop drawing SSD

Detailed Fabrication Drawings

Shop drawings that define each structural steel component’s size, geometry, welds, bolts, finishes and markings, enabling accurate fabrication.

Connection & Joint Detailing

Drawings showing precise connection types (e.g., shear, moment), bolt/weld specifications, plate thickness and orientation, ensuring structural integrity and correct assembly.

Assembly & Erection Drawings

Documentation that directs the sequence and orientation for onsite erection of prefabricated steel components, showing base plates, anchor bolts, out-of-plumb conditions and temporary supports.

Bill of Materials (BOM) & Marking Schedules

Detailed lists of steel sections, plates, bolts, weld consumables, markings and identifiers for each member, helping procurement and shop tracking.

Coordination & Clash Detection Drawings

Shop drawings developed with BIM tools (e.g., Tekla Structures) to ensure structural steel components are coordinated with other trades (MEP, architectural) and to minimise on-site conflicts.

Code & Specification Compliance Documentation

We convert Point Cloud data into MEP Models using Revit, including Mechanical Equipment (HVAC, Pumps, Fans), Electrical (Switches, Panels), Plumbing (Pipes, Fittings, Fire Extinguishers)

Structural Steel Detailing

- General Information: This section includes project-specific details such as the project name, location, drawing number, revision number, and scale.

- Title Block: The title block contains important information about the drawing, including the drawing title, the name of the detailer, and the date of creation.

- Plan Views: These views show the horizontal layout of the structural steel components. They provide information about column locations, beam positions, and connections.

- Elevation Views: Elevation views illustrate the vertical layout of the structural steel components. They show the height and arrangement of beams, columns, and other elements.

- Section Views: Section views are used to showcase specific details of connections, welds, and other critical areas. They provide a cross-sectional view of the steel components.

Benefits of shop drawing for structural steel detailing

Accuracy and Precision

Shop drawings provide precise details about the fabrication and installation of structural steel components. They specify dimensions, connections, and other critical information, ensuring that the steel elements fit together accurately and align with the design intent.

Coordination and Clash Detection

Shop drawings enable coordination between various trades involved in the construction process. They help identify clashes or conflicts with other building systems, such as mechanical, electrical, or plumbing systems, early in the project.

Clear Communication

Shop drawings serve as a communication tool between the design team, fabricators, and contractors. They provide a visual representation of the design intent and help all stakeholders understand the structural requirements and specifications.

Compliance with Codes and Standards

Shop drawings ensure that the structural steel components meet the relevant building codes, industry standards, and project specifications.

Measuring Our Success Through Your Growth

Industries We Serve

We have a BIM solution for everything your project demands.

HEALTHCARE

RESIDENTIAL

HOSPITALITY

RETAIL & COMMERCIAL

INFRASTRUCTURE

TRANSPORTATION

EDUCATION

ENERGY & INDUSTRIAL

DATA CENTRE

MIXED-USE

Why Choose Us

Precision Engineering

At ACURABIM we deliver highly accurate 3D modelling and drafting services tailored for the AEC industry whether architectural, structural or MEP systems.

Seamless Collaboration

We facilitate smooth coordination between architects, engineers and contractors through our BIM workflow that supports clash detection, real-time updates and shared data access

End-to-End Delivery

From 2D planning and 3D modelling to 4D sequencing and 5D cost integration, ACURABIM supports your project through all phases. Whether it's conceptual design or construction.

Cost & Time Efficiency

By using smart BIM processes, detailed drafting and thorough documentation, we help you reduce construction delays, avoid costly mistakes and optimise material usage.

General Questions

1. What are Steel Shop Drawing Services?

Steel shop drawing services involve the creation of detailed, accurate drawings used for the fabrication, assembly, and installation of structural steel components in construction projects. These drawings provide all the necessary dimensions, materials, connections, and assembly instructions for steel structures, ensuring they are fabricated and installed correctly on-site. Steel shop drawings are typically produced by steel fabricators or detailing contractors and are based on the original design and engineering drawings.

2. Why are Steel Shop Drawings Important?

Steel shop drawings are crucial for several reasons:

- Fabrication Accuracy: They ensure that steel components are fabricated accurately to meet the design specifications.

- Reduced Errors: By detailing every aspect of the steel components, shop drawings minimize errors in the fabrication and installation process.

- Coordination with Other Trades: Shop drawings help coordinate with other trades (e.g., electrical, plumbing, and HVAC) to ensure proper integration of steel elements within the overall building design.

- Clear Communication: They serve as a communication tool between engineers, architects, fabricators, and contractors, ensuring that everyone understands the project’s requirements.

- Installation Instructions: Steel shop drawings also provide precise information on how to install the steel components, helping contractors achieve smooth on-site assembly.

3. What Software is Used for Steel Shop Drawings?

Several software programs are commonly used for creating steel shop drawings, including:

- AutoCAD: A standard software for 2D detailing and drafting of steel shop drawings.

- Tekla Structures: A BIM-based software that allows for the creation of detailed 3D models and shop drawings for steel structures, commonly used for large and complex projects.

- Revit: A BIM tool used for both architectural and structural design, including steel detailing and generating shop drawings.

- Strucad: A software used for 3D modeling and detailing of steel structures.

- SolidWorks: Often used for designing and detailing custom or highly intricate steel components.

- Bentley ProStructures: A comprehensive tool for structural steel modeling and detailing.

4. What Are the Benefits of Using Steel Shop Drawing Services?

The key benefits of using steel shop drawing services include:

- Precision: Steel shop drawings ensure that every steel component is fabricated and installed to precise specifications, reducing the risk of errors on-site.

- Time Savings: Detailed shop drawings speed up the fabrication process and reduce delays caused by unclear or incomplete information.

- Cost Efficiency: Reduces the chances of rework or mistakes, helping to avoid costly delays or changes during construction.

- Improved Coordination: Steel shop drawings improve coordination between various teams involved in the project, including fabricators, contractors, and other trades.

- Regulatory Compliance: Professional shop drawing services ensure that the steel components meet safety and code requirements.

- Customization: Specialized detailing services can be provided for custom or non-standard steel components that require detailed planning and precise execution.

5. How Long Does It Take to Create Steel Shop Drawings?

The time it takes to create steel shop drawings depends on several factors, such as:

- Size and Complexity of the Project: Larger or more intricate steel structures may take longer to detail, while simpler designs will require less time.

- Level of Detail: Projects requiring highly detailed connections, custom components, or special fabrication techniques will take more time.

- Revisions and Approvals: The number of revisions required and the speed of the approval process can also impact the timeline.

Typically, creating steel shop drawings for a medium-sized project can take between 2 to 8 weeks, but larger or more complex projects may require several months.

6. How Much Do Steel Shop Drawing Services Cost?

The cost of steel shop drawing services varies based on several factors:

- Project Complexity: More complex projects with custom steel components or intricate details will cost more than simpler projects.

- Scope of Work: Services that involve 3D modeling, custom detailing, and extensive revisions can increase costs.

- Size of the Project: Larger projects with more steel components will require more time and resources to detail, leading to higher costs.

- Location: Costs can also vary depending on the region and the availability of skilled detailers.

On average, steel shop drawing services can range from $2,000 to $15,000 or more, depending on the size and complexity of the project.

Enquire Now

Our Work