Shop Drawing Service

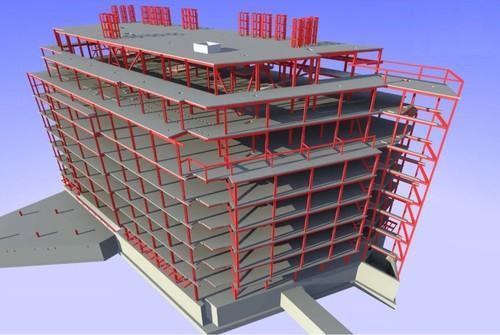

Shop Drawing Service plays a crucial role in bridging the gap between designers and vendors. It includes steel shop drawings, sheet metal shop drawings, woodwork shop drawings, and more. These working drawings display complete erection details and are essential for accurate fabrication and installation. Our team delivers highly precise shop drawings that are easily approved by government authorities. We offer Shop Drawing Services for commercial buildings, residential projects, and industrial structures.

- Home

- Services

- Structural Modeling Services

- Shop Drawing Service

How Steel Shop Drawings Services help

A Shop Drawing Service can generate an Advance Bill of Materials (ABM) early in the project, offering a clear understanding of the shapes and dimensions of the steel required for efficient workshop and yard management. By setting priorities in advance, it streamlines workflow and simplifies tasks to ensure smooth operations.

Outsourcing ABM through a professional Shop Drawing Service can lead to significant savings in time, cost, and manpower. It also enhances organization and efficiency in managing manufacturing tasks within the workshop. With accurate material estimates, it provides better insights into transportation needs and costs. Additionally, detailed assembly and general drawings improve execution speed and accuracy. This structured approach also supports compliance by aiding in timely government approvals, resulting in seamless project delivery.

Our Shop Drawing Services

Architectural Shop Drawings

Prepare detailed architectural shop drawings showing layouts, dimensions, materials, and finishes for on-site execution.

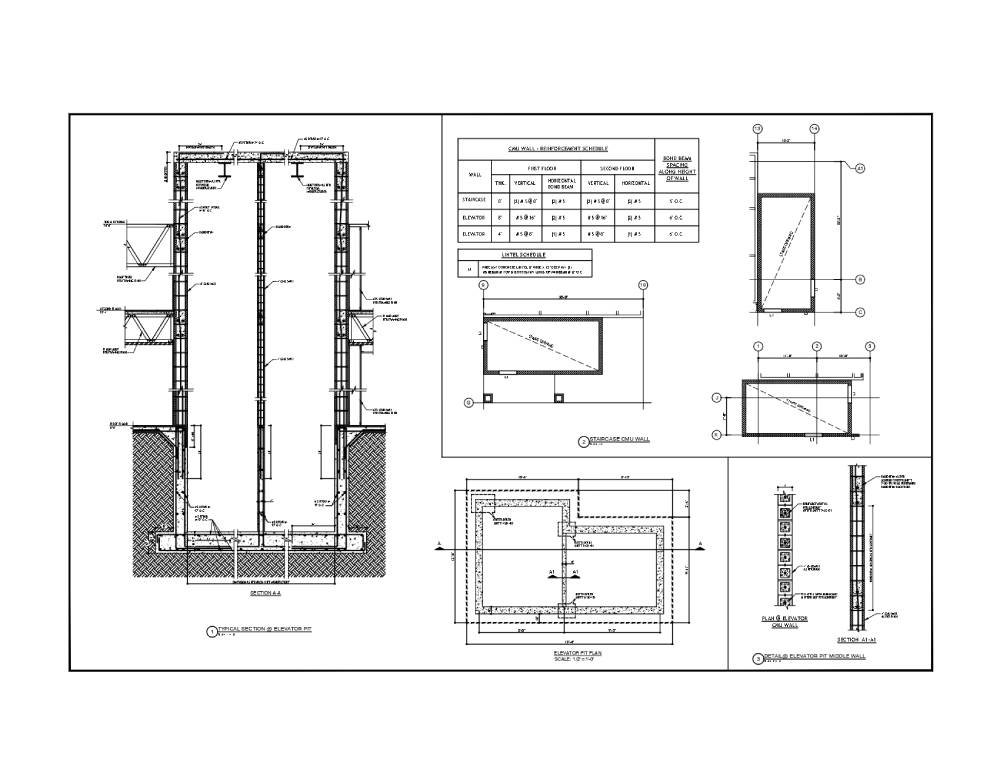

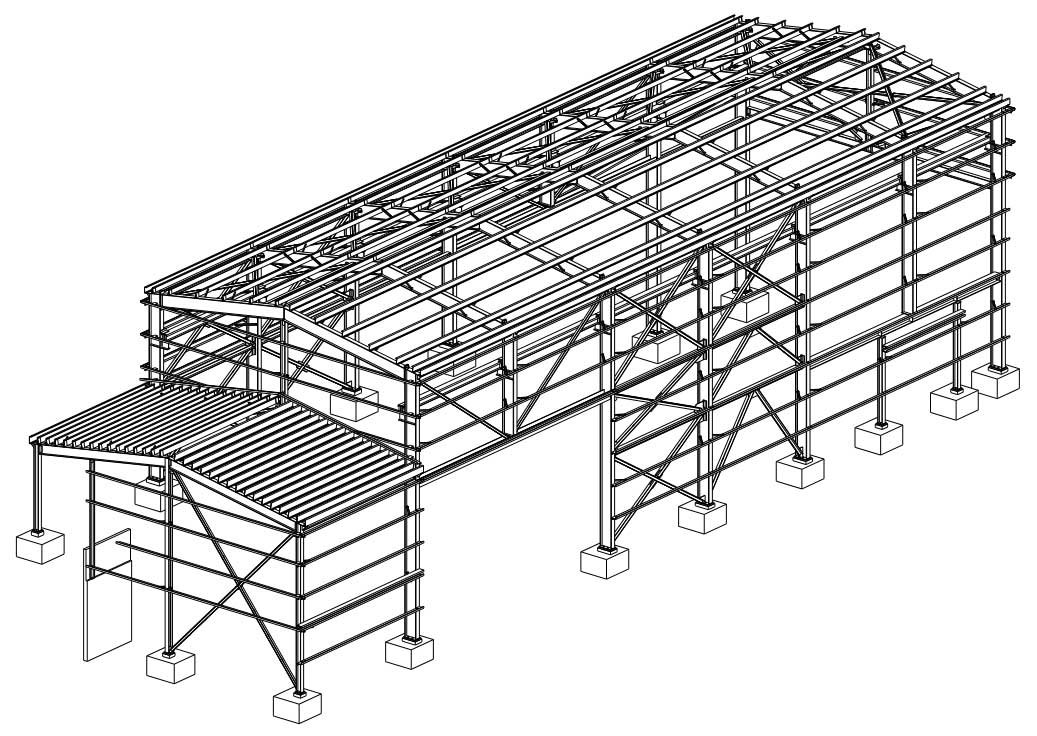

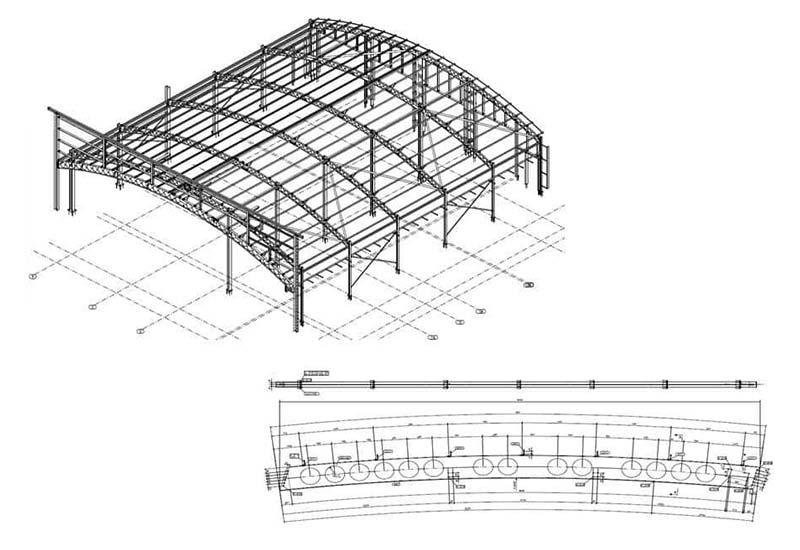

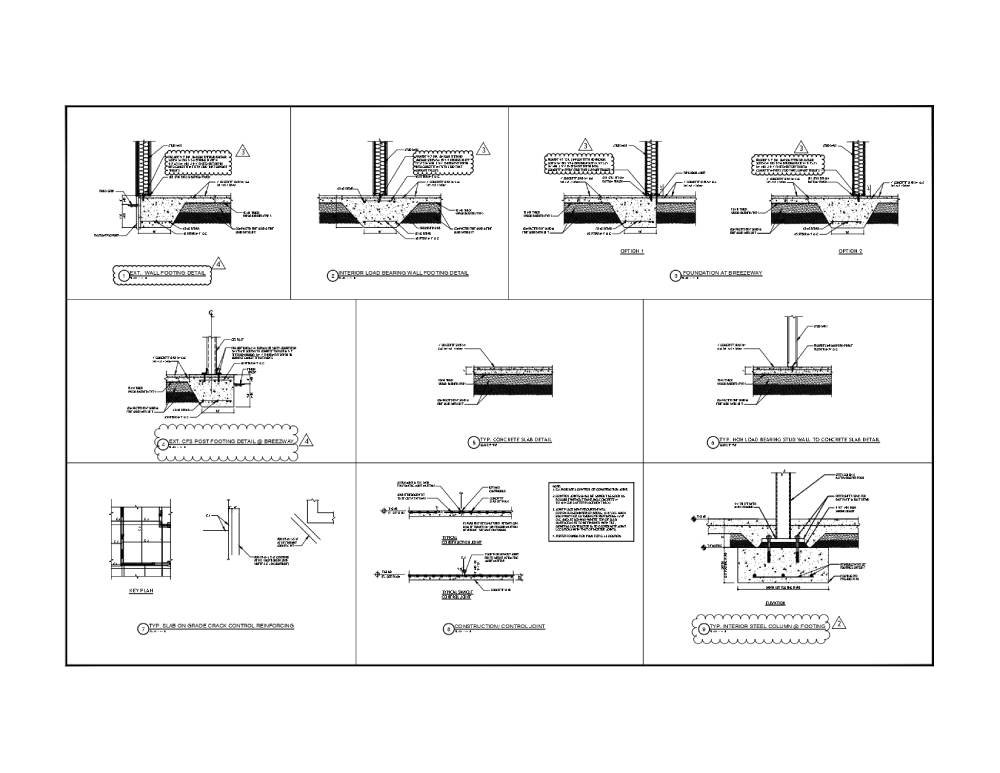

Structural Shop Drawings

Develop accurate fabrication and erection drawings for steel, concrete, and structural components.

MEP Shop Drawings

Create coordinated mechanical, electrical, and plumbing shop drawings ensuring

clash-free installation.

Coordination & Composite Drawings

Combine architectural, structural, and MEP drawings into one coordinated model

for seamless construction.

As-Built Drawings

Generate precise as-built documentation reflecting actual site conditions for

maintenance and future reference.

Quantity Take-off & Material Scheduling

Extract material lists, quantities, and schedules directly from shop drawings for efficient project management.

Measuring Our Success Through Your Growth

Industries We Serve

We have a BIM solution for everything your project demands.

HEALTHCARE

RESIDENTIAL

HOSPITALITY

RETAIL & COMMERCIAL

INFRASTRUCTURE

TRANSPORTATION

EDUCATION

ENERGY & INDUSTRIAL

DATA CENTRE

MIXED-USE

Why Choose Us

Precision Engineering

At ACURABIM we deliver highly accurate 3D modelling and drafting services tailored for the AEC industry whether architectural, structural or MEP systems.

Seamless Collaboration

We facilitate smooth coordination between architects, engineers and contractors through our BIM workflow that supports clash detection, real-time updates and shared data access

End-to-End Delivery

From 2D planning and 3D modelling to 4D sequencing and 5D cost integration, ACURABIM supports your project through all phases. Whether it's conceptual design or construction.

Cost & Time Efficiency

By using smart BIM processes, detailed drafting and thorough documentation, we help you reduce construction delays, avoid costly mistakes and optimise material usage.

General Questions

1. What is a Shop Drawing Service for Structural Steel Detailing?

A Shop Drawing Service for structural steel detailing involves creating highly accurate drawings that specify how steel components should be fabricated, assembled, and installed. These drawings ensure all structural elements meet design specifications and are essential for smooth construction execution.

2. What is the purpose of Shop Drawings in Structural Steel Detailing?

The purpose of shop drawings in structural steel detailing is to:

- Provide Fabricators with Accurate Information: Shop drawings offer the precise details fabricators need to cut, weld, and assemble steel components according to the design specifications.

- Ensure Accuracy and Quality: They minimize errors by providing clear, detailed instructions for fabricating each steel member, including dimensions, connections, and material specifications.

- Coordinate with Other Trades: These drawings help ensure that steel structures fit properly within the overall building design and coordinate with other trades like electrical, plumbing, and mechanical.

- Assist in Installation: Shop drawings offer clear instructions on how to install and assemble structural steel components in the field.

3. What Information is Included in Structural Steel Shop Drawings?

Structural steel shop drawings typically include:

- Detailed Dimensions: Exact measurements of steel components, including lengths, widths, and thicknesses.

- Materials Specifications: Information about the types and grades of steel to be used for each component.

- Welding and Bolting Details: Instructions on how steel pieces should be welded or bolted together, including welding symbols, bolt sizes, and placement.

- Connection Details: Specific details on how different steel members connect to each other, including connection types (e.g., shear connections, moment connections).

- Assembly Instructions: How each steel piece should be assembled, often including orientation, sequence, and any specialized assembly instructions.

- Fabrication Notes: Any special notes or instructions related to the fabrication process, such as cutting, bending, or forming requirements.

- Fabrication Sequence: The order in which the steel members are fabricated and assembled.

- Shop Markings: Identification numbers or marks for each part, allowing easy tracking and assembly in the shop.

- Coating and Finishing: Information about coatings, such as painting or galvanization, if required.

4. What are the Benefits of Using Shop Drawings for Structural Steel?

The key benefits of using shop drawings for structural steel detailing include:

- Enhanced Precision: Shop drawings help ensure accurate fabrication by providing detailed, specific information on each component, reducing errors and rework.

- Clear Communication: They serve as a communication tool between designers, fabricators, and installers, ensuring everyone is on the same page regarding the project’s details.

- Efficient Fabrication and Assembly: With clear guidance, fabricators can efficiently produce the steel components, and installers can follow easy-to-understand instructions, speeding up the construction process.

- Reduced Costs: Proper detailing and reduced errors mean fewer change orders, delays, and costly mistakes on-site.

- Compliance and Approval: Shop drawings are often reviewed and approved by engineers and architects to ensure that the steel components meet design specifications and safety standards.

5. What Software is Used for Creating Shop Drawings for Structural Steel Detailing?

Several software tools are commonly used for creating shop drawings for structural steel detailing, including:

- AutoCAD: One of the most widely used software for drafting and creating 2D shop drawings in structural steel detailing.

- Tekla Structures: A BIM-based software designed specifically for structural steel detailing, capable of creating 3D models and generating detailed shop drawings directly from the model.

- Revit: A BIM tool used for both architectural and structural design, which can also be used to generate shop drawings for structural steel elements.

- SolidWorks: Primarily used for 3D modeling and detailing, particularly for mechanical and custom steel components.

- Bentley ProStructures: A BIM software solution that allows for the creation of 3D steel models and shop drawings.

- Strucad: A 3D modeling and detailing software tailored to steel fabrication.

6. How Much Do Shop Drawings for Structural Steel Detailing Cost?

The cost of creating shop drawings for structural steel detailing varies depending on:

- Project Size and Complexity: Larger or more complex projects will cost more due to the level of detailing and the amount of work involved.

- Location: Costs can vary based on the region, as labor rates and the availability of skilled detailers may differ.

- Level of Detailing: Projects requiring highly detailed or custom steel components may incur higher costs.

Typically, structural steel detailing services can range from $1,500 to $10,000 or more per set of shop drawings, depending on the scope and complexity of the project.

Enquire Now

Our Work