Rebar Detailing

Acura is one of the leading firms for Rebar Detailing Services. Our team of rebar detailers having deep knowledge and well experience of secure the best of details, Working Drawing, and 3D modeling in Revit as well As Estimation of Bar bending Scheduling Services. Acura takes care of all the necessary IS Codes (Indian Standard), BS Code (British Standards), and other national Zoning According to their Standards.

- Home

- Services

- Structural Modeling Services

- Rebar Detailing

Rebar Detailing Services

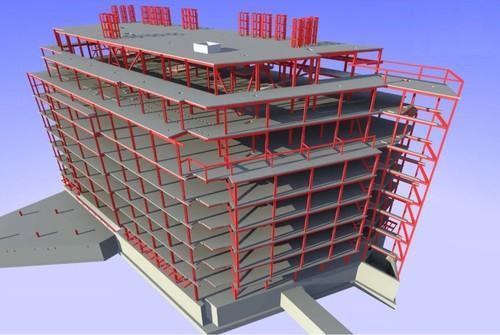

Rebar 3D Modeling

Create precise 3D reinforcement models showing bar placement, bending, and lap details for all structural elements.

Rebar Shop Drawings

Prepare detailed bar bending schedules (BBS), placement drawings, and

fabrication details for construction accuracy.

Concrete Reinforcement Detailing

Provide detailed reinforcement layouts for slabs, beams, columns, foundations,

and walls to ensure structural strength.

Quantity Take-off & BBS Generation

Generate accurate bar lists, quantities, and bar bending schedules directly from

3D rebar models.

Clash Detection & Coordination

Perform clash checks between rebar, concrete, and embedded items to avoid conflicts during construction.

As-Built & Revision Drawings

Deliver as-built reinforcement drawings reflecting site modifications for record and future maintenance.

Rebar Detailing

All the Standard code is the base outsourcing of rebar or Steel Detailing Services. Acura Provides the Design and Drafting as well as Detailing, our professional considers the site condition and made the changes accordingly to the geology condition of the site. So, the process of rebar work is one of the most required services for simplifying the work and reduced the cost of installation too.

It provides services that include detailing, creation of shop drawings and fabrication drawings, and estimating enables structural engineers, rebar fabricators, and steel erectors for more productive construction Structures in reinforced concrete.

Benefits of Rebar Detailing Services

Efficient Utilization

Services are used to avoid delays and waste of material.

Precise Detailing

Services accurately showed required anchors and laps details.

Rebar Assistance

It can also be outsourced, significantly saving time, cost, and manpower while ensuring smooth project execution.

Rebar Specifications

Each rebar is detailed showing diameter, length, shape, and quantities in rebar drawings.

Rebar Placement

The placement rebar in location and concrete cover is detailed in the drawings.

Bending Schedule

This schedule ensures precise cutting and bending of reinforcement bars, minimizing material wastage and optimizing usage.

Measuring Our Success Through Your Growth

Industries We Serve

We have a BIM solution for everything your project demands.

HEALTHCARE

RESIDENTIAL

HOSPITALITY

RETAIL & COMMERCIAL

INFRASTRUCTURE

TRANSPORTATION

EDUCATION

ENERGY & INDUSTRIAL

DATA CENTRE

MIXED-USE

Why Choose Us

Precision Engineering

At ACURABIM we deliver highly accurate 3D modelling and drafting services tailored for the AEC industry whether architectural, structural or MEP systems.

Seamless Collaboration

We facilitate smooth coordination between architects, engineers and contractors through our BIM workflow that supports clash detection, real-time updates and shared data access

End-to-End Delivery

From 2D planning and 3D modelling to 4D sequencing and 5D cost integration, ACURABIM supports your project through all phases. Whether it's conceptual design or construction.

Cost & Time Efficiency

By using smart BIM processes, detailed drafting and thorough documentation, we help you reduce construction delays, avoid costly mistakes and optimise material usage.

General Questions

1. What is Rebar Detailing?

Rebar detailing is the process of creating detailed plans and drawings for the reinforcement steel (rebar) used in concrete construction. These drawings outline the size, shape, length, bending, spacing, and placement of rebar in concrete structures, ensuring that the reinforcement is designed correctly to meet structural strength requirements and building codes.

2. Why is Rebar Detailing important?

Rebar detailing is crucial for several reasons:

- Structural Integrity: Properly detailed rebar ensures that the concrete structure can withstand stress, weight, and environmental forces, providing safety and durability.

- Code Compliance: Rebar detailing ensures the design complies with local building codes and regulations.

- Accuracy in Construction: Accurate rebar details help construction teams avoid mistakes during installation, ensuring the correct type, size, and placement of rebar.

- Cost-Effectiveness: Proper rebar detailing minimizes waste and reduces the need for rework during construction, saving both time and money.

- Preventing Structural Failures: Detailed rebar plans help to avoid common mistakes, such as incorrect placement or bending of reinforcement, which can lead to structural failure.

3. What is included in Rebar Detailing?

Rebar detailing includes the following aspects:

- Bar Schedules: A list detailing all the different types of rebar used in the structure, including bar sizes, lengths, and quantities.

- Rebar Layouts: Drawings showing the placement of each rebar element within the concrete formwork, typically at various levels and sections of the structure.

- Bending Schedules: Details on how each rebar should be bent, specifying angles, lengths, and shapes of the rebars.

- Dimensions: Precise measurements for the size, length, and spacing of the rebar to ensure it fits perfectly in the concrete framework.

- Connection Details: Information on how different pieces of rebar will be connected, such as tying or welding.

- Reinforcement Specifications: Specifications related to the type of steel (e.g., grade of rebar), coatings (e.g., epoxy-coated rebar for corrosion resistance), and other relevant details.

4. What are the benefits of Rebar Detailing?

The benefits of rebar detailing include:

- Accurate Construction: Ensures that the reinforcement structure is built to the exact specifications required for safety and stability.

- Reduced Errors: With accurate and clear drawings, the likelihood of errors during construction is minimized, which reduces costly delays and corrections.

- Faster Project Completion: With all rebar placement and fabrication details in place, workers can execute the rebar installation more efficiently, speeding up the construction process.

- Cost Control: Precise detailing helps in better planning and ordering of materials, which helps avoid overordering and reduces waste.

- Improved Quality Control: Detailed rebar drawings ensure that the correct type and quantity of materials are used, helping to meet quality standards.

5. What is the role of Rebar Detailers?

Rebar detailers are professionals who specialize in creating rebar detail drawings. Their responsibilities include:

- Interpreting Structural Drawings: Rebar detailers use architectural and structural blueprints to determine where and how reinforcement is needed.

- Creating Rebar Shop Drawings: These are the detailed drawings that indicate the layout, bending, and placement of rebar within concrete structures.

- Verifying Code Compliance: Rebar detailers ensure that all reinforcement designs meet local building codes and regulations.

- Collaboration: Rebar detailers work closely with structural engineers, architects, and contractors to ensure that the designs are feasible and optimized for construction.

6. What are the costs of Rebar Detailing Services?

The cost of rebar detailing varies depending on factors such as:

- Complexity and Size of the Project: Larger, more complex structures require more detailed drawings and therefore cost more.

- Number of Drawings: The more detailed drawings are required (e.g., multiple levels, sections, and structural components), the higher the cost.

- Project Location: Costs can vary based on location, due to differences in labor rates, software requirements, and local construction standards.

- Rebar Detailer’s Experience: Highly experienced or specialized rebar detailers may charge higher fees for their expertise.

On average, the cost can range from $500 to $5,000 or more, depending on the project’s scope, with larger projects costing significantly more.

Enquire Now

Our Work