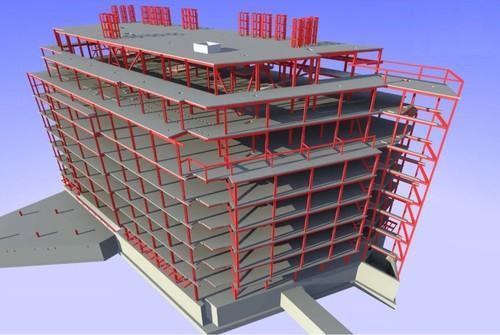

MEP 3D Modeling Services

Acura BIM provides detailed MEP 3D modeling services worldwide, including 3D MEP coordination and clash detection. We also provide MEP 3D Modeling, and detailed construction documents to retailers, homeowners, architects, and general contractors. Our MEP services include 3D MEP coordination and clash detection.

- Home

- Services

- MEP BIM Modeling

- MEP 3D Modeling Services

3D MEP Modeling Coordination in Revit

The integration of MEP systems in a 3D model also improves communication among stakeholders by providing a clear, visual representation of the project. This enables faster decision-making and more efficient project planning. Furthermore, with Revit’s advanced features, it’s possible to conduct real-time updates and adjustments, ensuring that all team members have the most current and accurate data at any given moment. Overall, 3D MEP modeling coordination in Revit enhances collaboration, reduces errors, and improves the efficiency of the design, planning, and construction phases, leading to faster project delivery and reduced costs.

Best Services offered by MEP 3D Modeling

Conversion

2D to 3D conversion from point cloud data

Detection

Clash detection and resolution of MEP.

Coordination

MEP design coordination with architecture and structure.

Quantity takeoff

It gives the high quality of work and improve productivity.

Components

MEP content creation or HVAC and MEP components.

Measuring Our Success Through Your Growth

Industries We Serve

We have a BIM solution for everything your project demands.

HEALTHCARE

RESIDENTIAL

HOSPITALITY

RETAIL & COMMERCIAL

INFRASTRUCTURE

TRANSPORTATION

EDUCATION

ENERGY & INDUSTRIAL

DATA CENTRE

MIXED-USE

Why Choose Us

Precision Engineering

At ACURABIM we deliver highly accurate 3D modelling and drafting services tailored for the AEC industry whether architectural, structural or MEP systems.

Seamless Collaboration

We facilitate smooth coordination between architects, engineers and contractors through our BIM workflow that supports clash detection, real-time updates and shared data access

End-to-End Delivery

From 2D planning and 3D modelling to 4D sequencing and 5D cost integration, ACURABIM supports your project through all phases. Whether it's conceptual design or construction.

Cost & Time Efficiency

By using smart BIM processes, detailed drafting and thorough documentation, we help you reduce construction delays, avoid costly mistakes and optimise material usage.

General Questions

What is MEP 3D Modeling?

MEP (Mechanical, Electrical, and Plumbing) 3D Modeling is the process of creating three-dimensional digital models of the mechanical, electrical, and plumbing systems within a building. These systems are critical for the building’s functionality and include HVAC (heating, ventilation, and air conditioning), electrical wiring, lighting, power distribution, water supply, drainage, fire protection, and other essential systems. The 3D modeling allows for better visualization, coordination, and management of these systems during design, construction, and operation.

What are the key benefits of MEP 3D Modeling?

Improved Coordination: MEP 3D modeling helps in the coordination between mechanical, electrical, and plumbing systems, reducing the risk of clashes or conflicts between systems.

Enhanced Visualization: 3D models allow designers, contractors, and stakeholders to visualize the entire MEP system within the context of the building, improving decision-making.

Clash Detection: The 3D model helps identify clashes or conflicts early in the design process, such as pipes interfering with ducts or electrical wiring running through load-bearing walls. This saves time and costs associated with rework during construction.

Cost Savings: By detecting potential issues early, MEP 3D Modeling minimizes the need for costly changes during the construction phase, reducing delays and material waste.

Accurate Documentation: MEP 3D models generate precise and comprehensive documentation, which is essential for the construction process and future building maintenance.

Operational Efficiency: During the building’s lifecycle, the 3D model can be used for maintenance and system upgrades, providing a more efficient way to manage the building’s MEP systems.

How does MEP 3D Modeling work?

MEP 3D Modeling involves the use of specialized software to create virtual models of a building’s mechanical, electrical, and plumbing systems. The steps typically include:

Design Integration: Incorporating MEP design requirements into a 3D model of the building’s structure (often developed in BIM software).

System Layout: Defining the layouts for HVAC, electrical, and plumbing systems, including ductwork, pipes, electrical cables, and other components.

Clash Detection: Using tools like clash detection software (e.g., Navisworks) to identify conflicts between MEP systems and the building structure.

Coordination: Coordinating between different disciplines (mechanical, electrical, plumbing) to ensure the systems fit together seamlessly without interference.

Documentation and Schedules: Creating precise construction drawings, material lists, and schedules for the installation and maintenance of MEP systems.

Collaboration: Sharing and updating the model among different project stakeholders, including architects, engineers, and contractors, ensuring everyone is working from the same plan.

What software is used for MEP 3D Modeling?

Several software tools are used in MEP 3D Modeling, including:

Revit: Widely used in BIM (Building Information Modeling), Revit allows for the detailed modeling of MEP systems, including HVAC, electrical, and plumbing components.

AutoCAD MEP: A version of AutoCAD tailored for MEP design, providing tools specifically for drafting, designing, and modeling MEP systems in 2D and 3D.

Navisworks: Used for clash detection and coordination of models, allowing different MEP systems and architectural designs to be reviewed for potential conflicts.

Trane Trace 700: Primarily used for HVAC system design and energy modeling.

Bentley Systems (AECOsim): A suite of tools for modeling and analyzing building systems, including MEP.

Tekla Structures: Mainly used for structural modeling but also supports MEP systems, especially for steel fabrication and coordination.

Plancal nova: A popular MEP-specific software for planning and managing installations for mechanical, electrical, and plumbing systems.

How does MEP 3D Modeling improve collaboration among teams?

MEP 3D Modeling enhances collaboration by:

Unified Platform: Providing a single, shared 3D model that integrates all building systems, allowing architects, engineers, and contractors to work off the same up-to-date information.

Real-Time Updates: As the model is updated, all stakeholders can access the latest version, reducing errors caused by outdated information.

Better Communication: Visualizing systems in 3D helps everyone involved better understand how components fit together, facilitating more effective communication and fewer misunderstandings.

Project Management: Tools like Revit and Navisworks offer project tracking features, helping teams stay on schedule and resolve issues faster.

What are the costs of MEP 3D Modeling Services?

The cost of MEP 3D Modeling services can vary based on:

Project Complexity: More complex buildings or systems (e.g., high-rise buildings, complex HVAC designs) will incur higher costs.

Scope of Work: The more detailed the MEP design and the number of systems being modeled, the higher the cost.

Software and Tools Used: The type of software and tools required can influence pricing, especially if specialized software is needed.

Project Timeline: Tight timelines may require more resources, leading to higher costs.

Location: Pricing may also vary depending on the region and labor costs in that area.

Typically, MEP 3D Modeling services may cost between $50 and $150 per hour, depending on the factors mentioned. Large projects may range from $10,000 to $100,000 or more for comprehensive modeling.

Enquire Now

Our Work