Stages of Designing Development in the construction sector

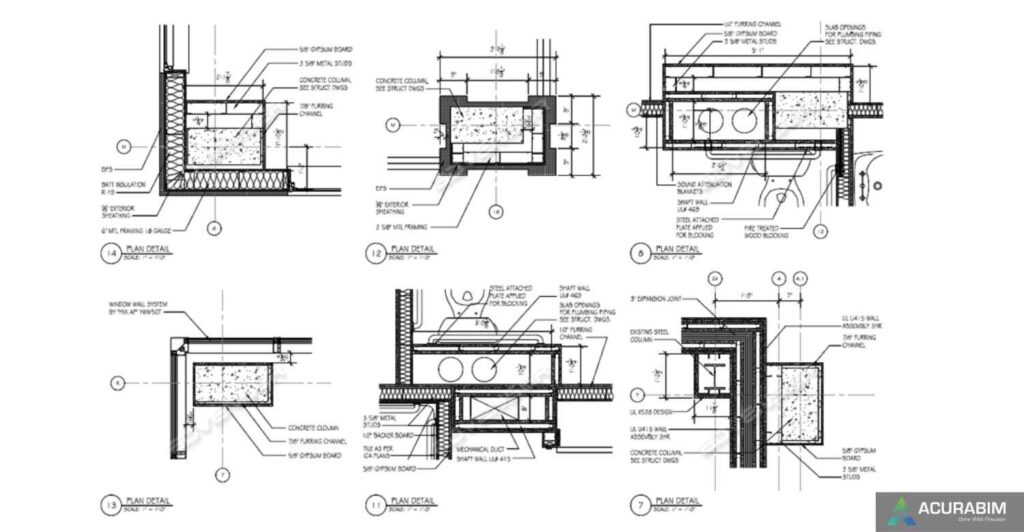

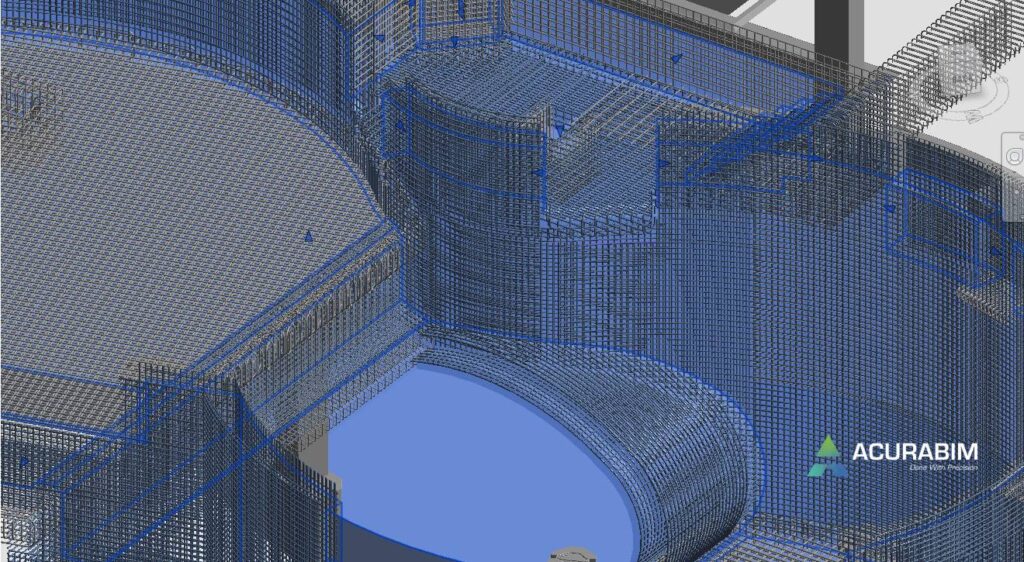

Stages of Designing Development in the construction sector (SD, DD, and CD): Work must be done in stages to have a comprehensive view on design, construction, and project completion. Every stage aims to maintain building projects on schedule, under budget, and in compliance with building codes. Architects require stakeholders to be informed and active throughout the whole design process in order to make significant decisions early on for major projects. Design Development (DD), Construction Documents (CD), and Schematic Design (SD) are terms used in the construction industry, respectively. In order to increase productivity and cut expenses, AEC companies now prefer to outsource their 3D BIM modelling requirements to BIM service providers. Three efficient architectural design procedures are used to separate the design period. Before beginning the following step, each phase must first be approved by the customer. Please refer to the following explanation for better overview of each topic: 1. Schematic Design (SD) In Schematic Design (SD), an outline framework is created in the owner’s presence by the architect, designers, and consultants. The project is conceptually planned, with scale, shape, and relationship diagrams generated. The Architect must also think about project permissions and jurisdictional needs at this phase. This phase incorporates the requirement for sustainable design integration through LEED. During Schematic Design, the project’s architectural plans may change multiple times. This aids the team’s evaluation and comprehension of the project’s goals and objectives. Planners, designers, and other experts with specialised knowledge may be included in the schematic design. At the very end of the Schematic Design phase or the beginning of the Design Development phase, engineering teams get involved. 2. Design Development (DD) The Design Development phase advances the work from the Schematic Design (SD) stage by planning structural systems, building systems, building materials, etc. The necessary dimensions are provided for important construction components, and code compliances are established and verified. During this stage, construction drawings are created based on a list of contractor standards or guidelines. Based on information learned during the Design Development Phase, the Schematic Design (SD) may need to be modified. 3. Construction Documents (CD) To provide a complete record of the design process, construction records are created. The architect and owner must agree the designs and budget before construction paperwork may be created. Design teams create a set of blueprints and specifications that outline the specifics of the whole project during this phase, which does not involve any design modifications. Construction documents include information on materials, mechanical and structural systems, etc. Conclusion It might be motivational to imagine projects on drawings. Architectural stages guarantee the timely and efficient completion of building projects. These procedures are used by architects to finish the design within a predetermined time frame.

Stages of Designing Development in the construction sector Read More »